ART For Human Possibilities

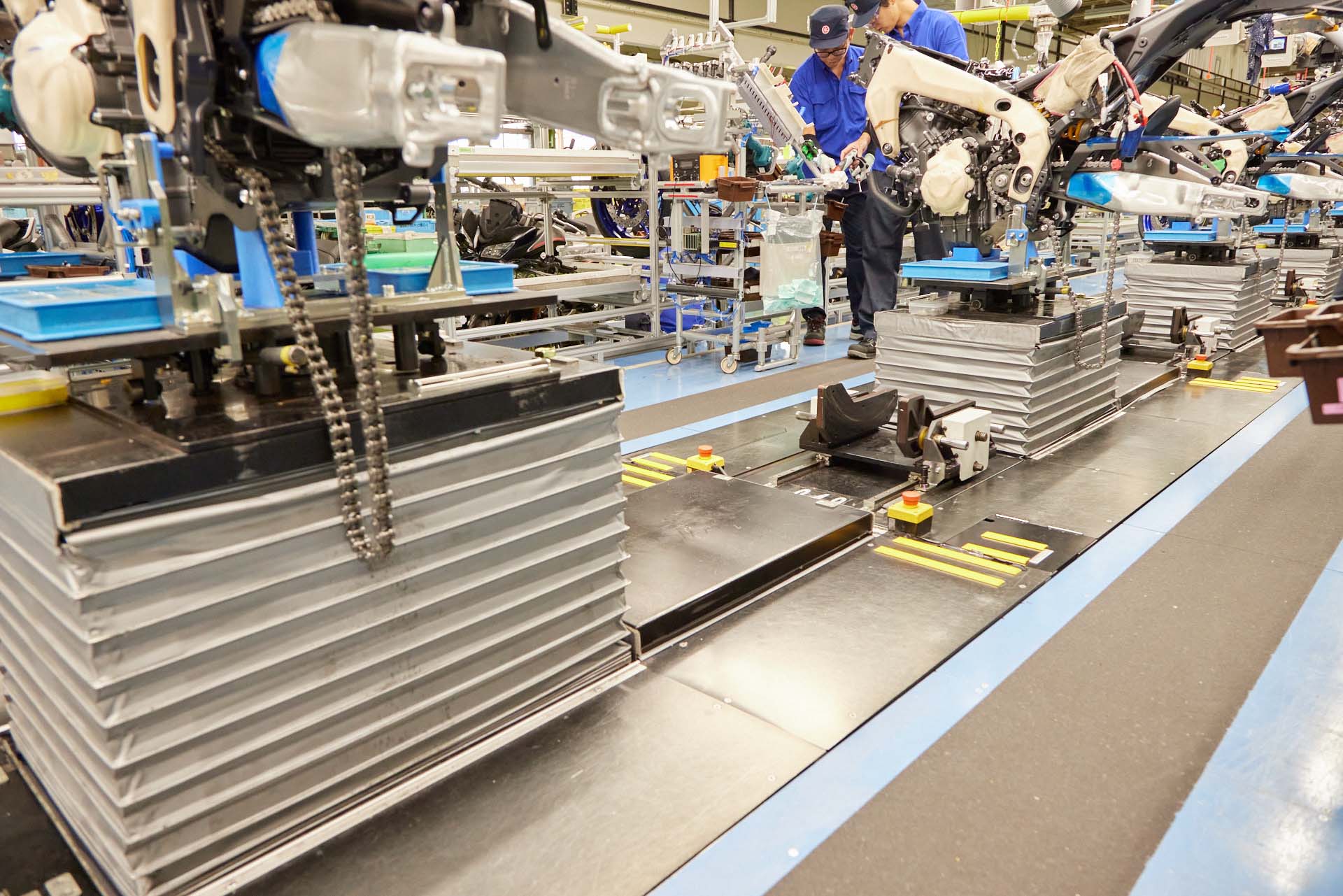

The motorcycle assembly factory at Yamaha Motor headquarters in Japan is where various products destined for markets around the world are born, and the facility is in the midst of transforming into a smart factory.

Dynamic innovations to production processes are underway on the factory floor, and with the number of assembly lines halved in just three years, the way the factory even looks is undergoing rapid changes.

Every day, approximately 9,000 different types of parts go into assembling various products at Yamaha Motor’s motorcycle assembly factory, with some 600,000 parts being used every day. Completed products are shipped from this facility to customers all around the world, and if you were to only watch the products arriving one by one at the factory’s loading bay, that part of the production process may appear to be rather simple. However, behind that simplicity lies a sophisticated simulation that responds to often fluctuating production plans.

“This is often a surprise to most people, but motorcycles are somewhat of a seasonal product. Because of the fluctuating demand, the difficulty posed by efficiently producing various kinds of products in small lots has been a challenge for us for quite some time,” explains a member of the Assembly Engineering Division. “If we were always producing a set volume of the same thing every day, we could use simpler equipment and production setups. However, this creates an inefficient situation in which you have one line operating at full capacity day and night, while the adjacent line lies idle.”

Automated guided vehicles (AGVs) began full-scale operation in the factory last year and are providing a solution to Yamaha’s longstanding problem of high-mix, low-volume production. They can be linked together to form an assembly line or they can disconnect from the line and move to the next assembly process on their own. Called the “AGV Bypass Method,” it is an innovative production method that replaces the conventional conveyor style of product assembly.

The Assembly Engineering Division member continues: “For example, when we’re running several models on a line at the same time, the number of parts to fit and work time required for each process naturally differs. So, an AGV carrying a model that doesn’t require the next process on a line will branch off from it and automatically head over to where its next required process is and merge in. We decided to call this the ‘bypass method’ because it works just like a bypass, allowing you to avoid a frequently packed road in order to get to your destination faster.”

And that’s not all it does. The AGVs move through the factory not only carrying bikes being assembled but also information about each product, process, and operator. The unit sends assembly instructions to the tools and equipment at each destination, and optimizes the height of the lift to suit the height of the operator and the work process. Furthermore, it has the adaptability and versatility to respond to sudden production requests for just one unit, representing a major innovation toward addressing the persisting problems with high-mix, low-volume production.

“The AGV Bypass Method not only improves production efficiency but also contributes to reforming work styles and energy savings,” he explains. “We have created a system that can help us to flexibly respond to the future diversification of our Monozukuri, including the spread of electric motorcycles.”

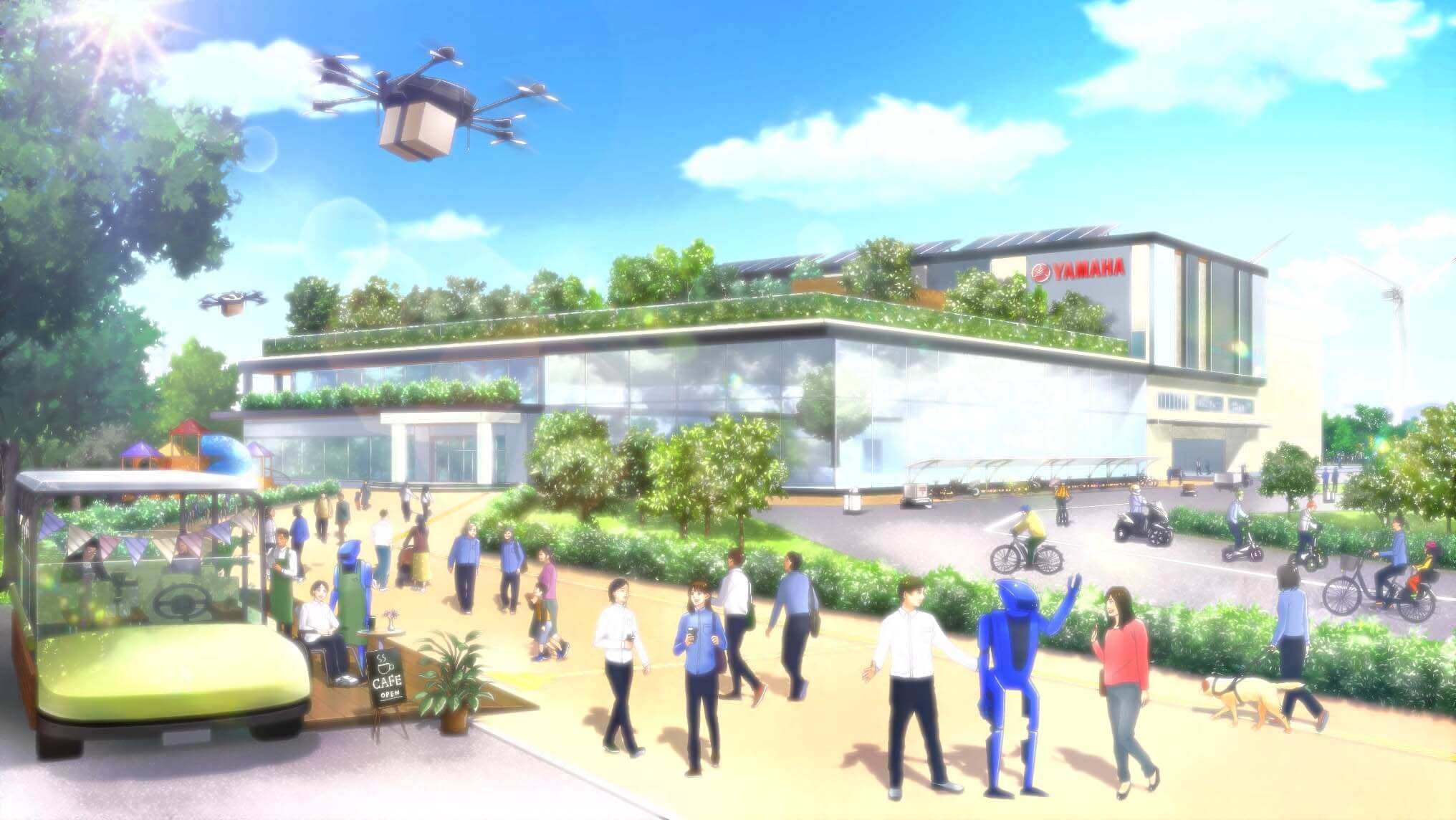

By combining advanced digital technologies with our decades of production expertise and know-how, Yamaha Motor’s goal is to create smart factories where everyone brings ample energy and drive to their work. And to that end, Yamaha’s factories are beginning to transform inside and out.